LDPE is used for manufacturing various containers, dispensing and squeeze bottles, tubing, plastic parts of computer components, moulded laboratory equipment and many caps and closures.

HDPE (High Density Polyethylene) bottles are the best choice for medicines, foods, and beverages because they have no reaction to the ingredients of items stored inside them. HDPE can withstand most strong mineral acids, bases and has excellent resistance to chemicals.

Tablets and capsules are well protected. Blister packs are portable, compact and easy to handle.

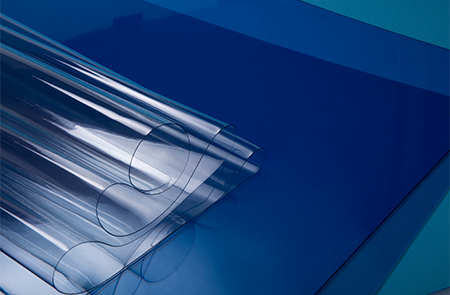

PVC (Polyvinyl chloride) & PVDC (Polyvinylidene dichloride) is to create tamper-resistant seals in food, beverage and pharmaceuticals industry, while rigid film is suitable for packaging materials such as clamshells

Blister packaging, commonly known as unit dose packaging, is used in the pharmaceutical industry for packaging medicine. In blister packaging, a plastic sheet is thermoformed to form multiple cups or blisters that hold the product. Blister packaging is used in multiple areas and not just pharmaceuticals.

An aluminium foil is used to make a push-through closure called lid film or blister film. Following this, the tablets and capsules are well protected and hygienically protected. Blister packs are portable, compact and easy to handle

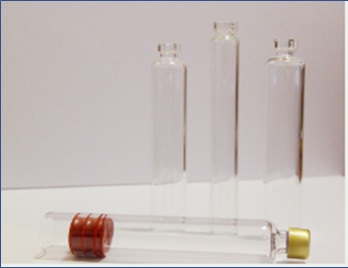

In the pharmaceutical industry, Glass vials are best used for packaging solids and non-aqueous preparations like tablets and powders.

Tubular vials offer transparency comparable to glass. Due to their excellent barrier properties, high chemical resistance and breakage resistance, these vials are recommended for emergency drugs, vaccines, diagnostic products and contrast media.

Rubber stoppers are broadly used for pharmaceuticals to preserve parental drug properties that are sensitive in nature. Serum Stoppers and Lyophilizing Stoppers are available in different designs and sizes in various polymers.

Euro head caps are used to prevent the plastic from getting into the drug solution, thereby preserving quality.

Rubber plunger is used to protect drugs from contamination by providing an effective barrier minimizing interaction between the drug and the closure while maintaining container closure integrity.

The insert allows you to dispense of the liquid contents with a lot more control than you would by pouring it out. This makes this cap ideal for products such as eye drops, food colourings and essential oils.